How Do You Use Laddermate?

According to the UK Ladder Association, falls from working at heights are among the most common workplace accidents, accounting for almost 25% of all work-related fatalities and 8% of non-fatal injuries yearly. A significant proportion of these cases involve falls from access equipment, such as ladders, which the Health and Safety Executive (HSE) says account for 40% of falls in the food and beverage industry.

To mitigate falls from ladders in the workplace and the lawsuits that follow, it’s critical to ensure the safety of employees working at heights. Laddermate is the latest innovation designed to enhance ladder safety and adherence to Working at Heights Regulations. Read on to discover everything you need to know about Laddermate, including what it is, its importance, and a step-by-step guide on how to use Laddermate.

What is a Laddermate?

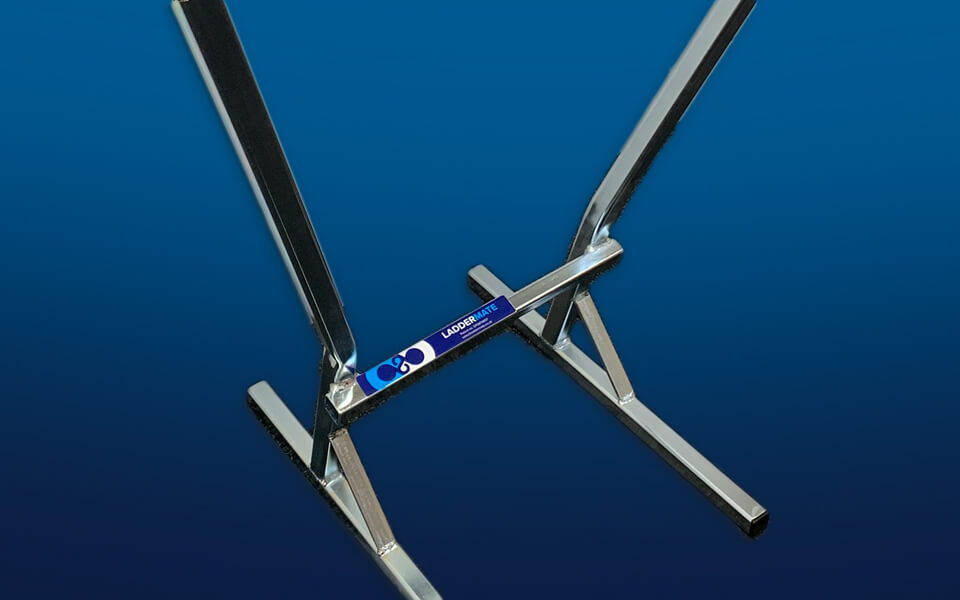

Laddermate is a safety device that reduces the risk of outward ladder slip. It is fitted at the ladder’s base to minimize the amount of flex or outward ladder bounce, ensuring users working with ladders feel more secure. The device features a larger trapezium-shaped base that effectively increases the ladder base to offer more lateral stability, unlike when using the ladder alone. With Laddermate braces, users can erect the ladder to the recommended angle, depending on the ladder’s configuration.

The working principle of Laddermate

After setting up a ladder against a wall, it forms a triangle, which is the best shape for a strong structure. When used on its own, the chances of the ladder slipping or bouncing outward are high, exposing users to safety risks. That’s where Laddermate comes into play. The safety device creates a triangle within the larger triangle that the ladder creates with the wall, thus enhancing its strength and stability.

By harnessing the principles of applied mathematics, Laddermate braces divert the downward force that users exert on the ground back towards the wall. When used as recommended, Laddermate prevents the ladder from slipping or bouncing outwards from the wall.

Even if you have a ladder with free-running wheels – which make the ladder slip by itself when leaned against a wall – Laddermate enables users to safely climb the ladder without the wheels rolling. In fact, multiple workers can use the wheeled ladder simultaneously without slipping outwards.

How to use Laddermate

The following is a step-by-step procedure for assembling and installing Laddermate:

- From a stowed position, slide apart the two sections of the Laddermate, and then reverse one of them and slide one side of the cross member into the other.

- Set the ladder against the wall correctly, and then install Laddermate. The device is mounted from the wall side of the ladder between the first and second rungs, with the side labelled ‘TOP’ being the uppermost point of the brace.

- Place the H-shaped lower legs on top of the lowest rung and stretch the cross member outward until it touches the inside of the ladder’s vertical supports, also known as stiles.

- It’s critical to ensure you have four contact points between Laddermate and the rungs. The H-shaped trapezium base touches the inside of the stiles, and the long, splayed section touches the ground on the wall side. In case you don’t meet any of these parameters, remove Laddermate, adjust the ladder angle, and refit it as recommended.Suppose you want to position the ladder on a ground sloping away from the wall; in that case, install Laddermate between the second and third rungs so long as the ladder is still at the recommended angle.In other circumstances, the ground may be sloping sideways, requiring you to first level the ladder in a safe position. Instead of extending the cross member to the full width of the stiles, stop short a few inches and twist the Laddermate to accommodate the slope. Still, ensure you have four contact points with the first and second rungs.

The importance of using Laddermate

Using Laddermate offers several benefits, including the following:

- It significantly reduces the risk of an outward slip or bounce.

- It provides a stable ladder base by reducing the amount of outward flex to ensure user safety.

- It features a trapezium-shaped base that extends the effective base of the ladder, providing more lateral stability.

- Assembling and installing Laddermate is quick and easy. The process takes less than five seconds. That incentivizes people to use the safety device. Most people are discouraged from using safety equipment if the installation process takes too long, especially when they are paid on a bonus basis.

- Ensures users set up the ladder at approximately the recommended angle. However, the angle varies based on the ladder’s configuration.

- For employers, Laddermate costs less than paying a second person to foot the ladder. Besides, once you purchase it, it serves you for years.

C&C Fabrications manufactures quality and long-lasting metal fabrications to suit your industrial needs. We also fabricate Laddermate braces to help you alleviate injuries and fatalities among employees working at heights using ladders. Contact us today by calling 01977 670 067 for a Laddermate brace to ensure you fulfil your health and safety mandates.